Parameter:

| |

| |

| |

| 500W 800W 1000w 1500w 2000w 3000w~40000w(can be customized) |

| |

| France Schneider Servo System |

| |

| |

| |

| |

| 1300*2500mm 1500*3000mm (can be customized) |

| |

| |

| |

| |

| |

| |

PS.All the working area and specifications can be customized according to your requests |

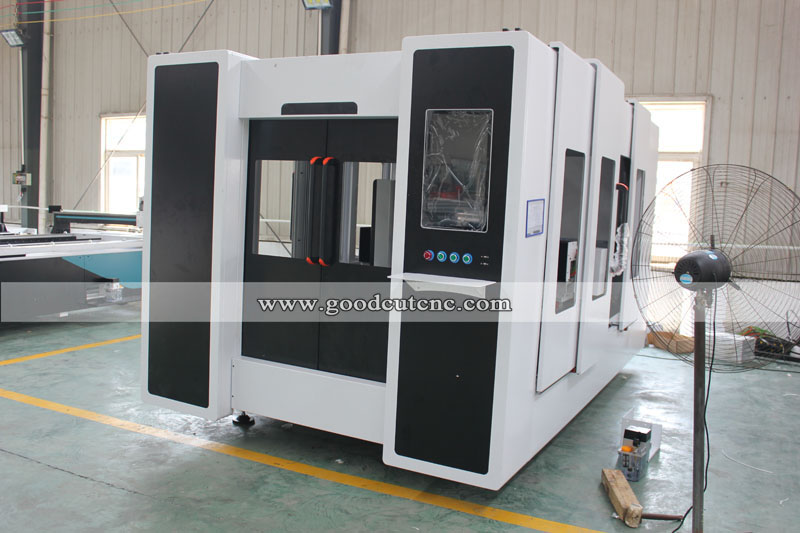

6x12 high power fiber laser metal cutting machine GC1530FC features with cutting speed, high power laser source (1000W, 2000W, 3000W, 4000W, 6000W, 8000W,12000W,15000W,20000W,40000W) and higher quality cuting result compared to other cutting solutions. It adopts the most sophisticated America IPG laser, combining CNC machinery designed by our company and high strength welding body, after standard heat treatment and process machining by large CNC milling machine.

Advantages:

1. Compact structure, small floor area.

2. Stability and reliability of light path system and control system.

3. High performance and low operating cost, famous IPG fiber laser with up to more than 100 thousand hours life-cycle.

4. Higher cutting quality and efficiency, cutting speed is up to 40 m/min with appearance and beautiful cutting edge.

5. High precision serve motors, lead screws and guide ways with famous brands to ensure the efficiency and accuracy, greatly increasing the stability and reliability.

Features:

1. Equipped with High power Fiber laser generator and can do cutting of any graphics .

2. Stable and good deformation resistance capability. Aging process technology ensures durable in use and accuracy of the machine.

3. Automatic following focus device realizes dynamic focus continuous cutting on materials with different thickness.

4. The working table is equipped with universal wheel and pneumatic loading device (optional), which saves labor, avoids metal sheet damage and ensures good cutting quality.

5. Separate digitalized operating table and remote controller is convenient for operation. There are several input modes of USB flash disk data copy, USB cable data transmission, network connections and other data transmission methods.

6. Standard collocation of automatic nesting software and optional collocation of auto-recognition cutting, save materials and improves working efficiency.

7.The machine can be equipped with integrated rotary device or detached rotary device and can do fixed position punching, notching and cutting metal pipes.

Appication:

Metal Material :

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Metal Industries :

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Package :

1. Strong water resit bottom in plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Pre-Sale Service:

1. Free sample cutting service:For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

2. Progressing Solution Design:According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

3. Customized machine design:According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.